Hv3 Flux

HV3 Flux-Free Nitrogen Metal cap sealing Vacuum Reflow Soldering and Brazing oven Model: HV3 Application: IGBT/DBC Power

Basic Info.

| Model NO. | HV3 |

| Max. Cool Down Ramp | 60-120/Minute |

| Cooling Way | Nitrogen/Water-Cooled (Shell, Heating Plate) |

| Max. Heat up Ramp | 120c/Minute |

| Voltage | 220V 25-60A |

| Weight | 360kg |

| Control Deviation | +/- 1°c |

| Heating Plate | Sic Coated Graphite |

| Max Temperature | 500 C |

| Heating Elements | Infrared Heating Lamps |

| Maximum Vacuum | 1X10-6bar |

| Soldering Area | 260*240mm |

| Chamber Height | >=100mm |

| Process Environment | Nitrogen, Formic Acid |

| Transport Package | Polywood Case and Foam |

| Specification | 950*1200*1100mm |

| Trademark | TORCH |

| Origin | Beijing, China |

| HS Code | 8514101000 |

| Production Capacity | 100 Set/Year |

Product Description

HV3 Flux-Free Nitrogen Metal cap sealing Vacuum Reflow Soldering and Brazing oven

Model: HV3Application:

IGBT/DBC

Power Semiconductors

Sensors

MEMS Devices

DIE Attachment

High Power LED

Hybrid Assembly

Flip Chip

Package Sealing

Feature of the vacuum reflow oven:1. Soldering temperature: the maximum soldering temperature of HV3 vacuum eutectic furnace is ≥ 500 ºC. 2. Vacuum degree: limit vacuum degree ≤ 10-6 PA working vacuum: 10-4 PA. 3. Effective welding area: ≥ 260mm * 240mm 4. Furnace height: ≥ 100mm, customized for special height. 5. Heating method: infrared heating at the bottom + infrared heating at the top. The heating plate adopts semiconductor silicon carbide graphite platform. It is not easy to deform after long-time use, and has high thermal conductivity, making the surface temperature of the heating plate more uniform. 6. Temperature uniformity: within the effective soldering area ≤± 2%. 7. Heating ramp:120 ºC / minute. 8.Cooling ramp: 60-120 ºC / minute (the ramp of no-load, temperature cooling from 100 ºC).9. Meet the soldering requirements of soldering materials temperature≤ 500 ºC. For example: In97Ag3, In52Sn48, Au80Sn20, SAC305, Sn90Sb10, Sn63Pb37, Sn62Pb36Ag2 and other preforms (can be soldered without flux eutectic), solder paste of various components, and curing of materials below 500 degrees.10. Soldering void rate: After a large number of customer verification, when HV3 vacuum eutectic furnace solder with soft solder, the void rate can be controlled between 0-3%.

Vacuum furnace Technical parameter:

Model | HV3 |

Soldering Size | 260*240mm |

Furnace height | 100mm(other Hights is optional) |

Maximum Temperature | 500ºC |

| vacuum | ≤3Pa with mechanical pump,≤10-4Pa with molecular pump |

Heat up ramp | 120 ºC / minute |

Cool down ramp | 60-120 ºC / minute |

Voltage | 220V, 25-60A |

Rated Power | 18KW |

Weight | 360kg |

Dimension | 600*600*1300mm |

Wight | 250KG |

The maximum heating rate | 120ºC/min |

The maximum cooling rate | Only water-cooled 60ºC/min, Air-cooled + water-cooled 120ºC/min |

Cooling Way | Air-cooled / water-cooled (shell, heating plate) |

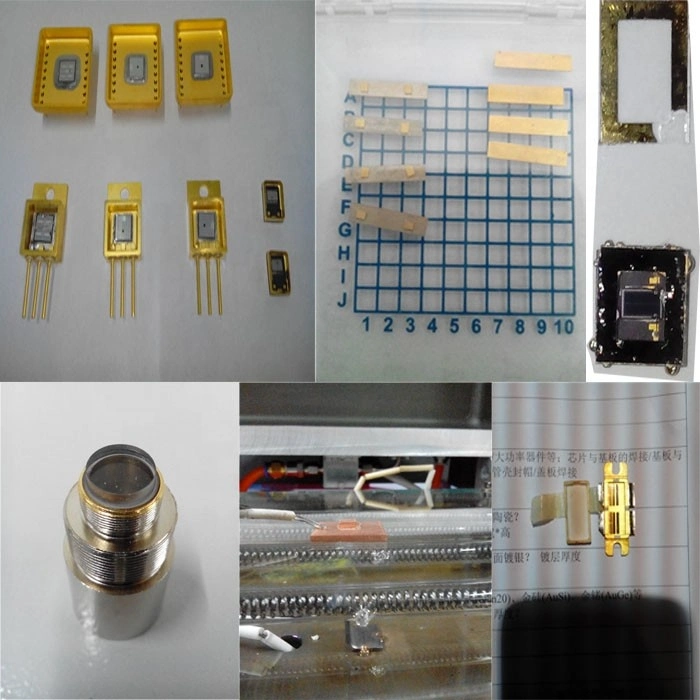

Soldering result:

Company information:

Send to us