Electrode Oven Drying for Turmeric

Product Description GENERAL DESCRIPTIONMC hot air circulating dryer uses is equipped with low-noise and thermostable axi

Basic Info.

| Model NO. | MCHG96 |

| Material Status | Powder, Strap, Bulk |

| Drying Medium | Superheated Steam, Air |

| Operation Pressure | Atmospheric Pressure |

| Operational Method | Intermittent |

| MOQ | 1set |

| Color | Silver |

| Power | 105kw |

| Quantity | 2800kg |

| Transport Package | Wood Crate |

| Specification | 6500*2400*2700 mm |

| Trademark | Mingchao |

| Origin | Zhucheng Shandong |

| HS Code | 4546789 |

| Production Capacity | 100/Year |

Product Description

Product Description

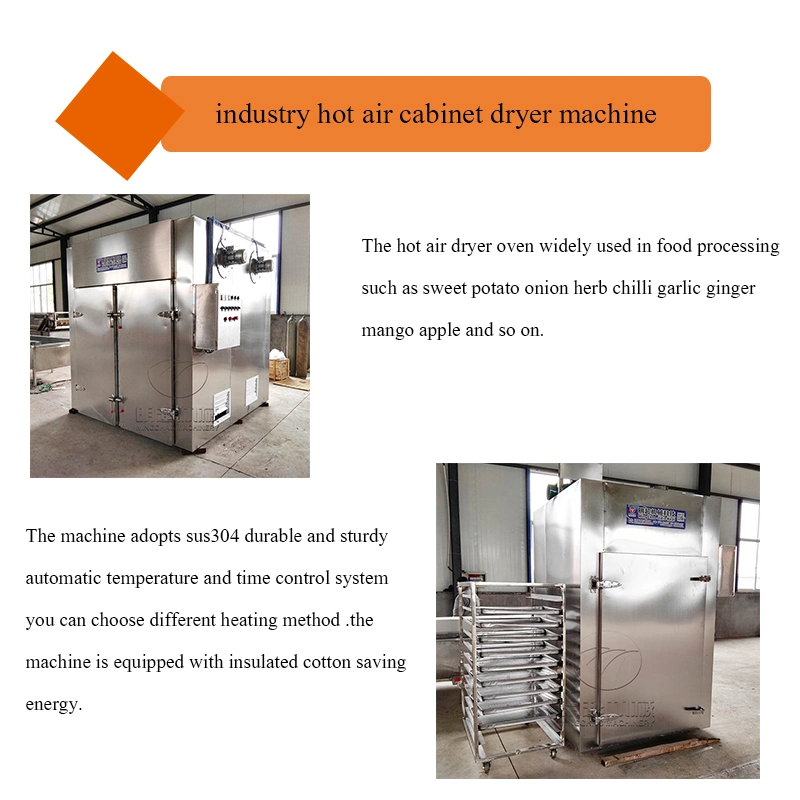

GENERAL DESCRIPTIONMC hot air circulating dryer uses is equipped with low-noise and thermostable axial flow fan and automatic temperature control system. The entire circulatory system is sealed, improving the thermal efficiency of oven from traditional 3-7% in drying room to the current 35-45%, with the highest thermal efficiency up to 50%. The design success of GR hot air circulating oven make our hot air circulation oven has reached the advanced level at home and abroad. It has saved a lot of energy for our country and improved the economic efficiency of enterprises.

Equipment Parameter

| Model | Size | Cart(set) | Baking pan(Piece) | Power source | Heating method | Operating temperature | Size of baking pan | Control system | Steam pressure | Weight/kg |

| MC-HGF-24 | 1400*1400*2600mm | 1 | 24 | Customize | Steam heating or electrical heating | 0-300ºC | 640*460*45mm | Automatic control | 10.0.2-0.8Mpa(2-8kg/com) | 500 |

| MC-HGF-48 | 1400*2400*2600mm | 2 | 48 | 11.0.2-0.8Mpa(2-8kg/com) | 800 | |||||

| MC-HGF-96 | 2400*2400*2600mm | 4 | 96 | 12.0.2-0.8Mpa(2-8kg/com) | 1000 | |||||

| MC-HGF-144 | 3500*2400*2600mm | 6 | 144 | 13.0.2-0.8Mpa(2-8kg/com) | 1500 | |||||

| MC-HGF-192 | 4500*2400*2600mm | 8 | 192 | 14.0.2-0.8Mpa(2-8kg/com) | 2000 | |||||

| MC-HGF-288 | 5500*2400*2600mm | 12 | 288 | 15.0.2-0.8Mpa(2-8kg/com) | 2800 | |||||

| Note | We can design the equipments depend on the requirements | |||||||||

CHARACTERISTIC1. Heating sources include steam, electricity, far infrared, dual-use of steam and electricity, all for users to choose;2. Using temperature: steam heating 50 ~ 140ºC, the highest 150ºC;3. Electricity, far infrared temperature 50 ~ 350ºC;4. It is equipped with automatic control system and computer control system for users to choose;5. Commonly used steam pressure 0.02-0.8Mpa (0.2 ~ 8kg / m2);6. It is equipped with electric heating, valued 15KW calculated according to type I, practical 5-8kw / h;7. If there is any special requirement please specify in order.Price of non-standard oven is negotiable.Please specify in order if using temperature is more than 140ºC or less than 60ºC.Our baking car and baking tray are in uniform size, so they are interchangeable;Baking tray size: 640 × 460 × 45 (mm)

Application of dryer machine It is suitable for the material and product hot solidification and dry de-watering in the pharmaceutical, chemical, food, farming, side-product, aquatic product, light industries, heavy industries and others industries. Such as: raw material medicine, crude drug, prepared herbal medicine of Chinese traditional medicine, plaster, powder, particle, drinking agent, pill, packing bottle, pigment, dyestuff, de-watering vegetable, dried fruit piece, sausage, plastics, resin, electric component, baking varnish and etc .

Features of dryer :

1, vegetable drier , high thermal efficiency, save energy.2, the use of forced ventilation effect, and equips with adjustable air distributing plate, uniform material drying, Heat source can use steam, hot water, electricity, far infrared, choose widely.3, low noise, running balance.Temperature control, easy installation and maintenance.

Service:pre-sale service

We Invite customers to visit our company and communicate on technical requirements face to face.

sale service

Responsible for debugging the equipment according to customers' requirements of various technical data. Our engineers will train our customers about equipment features and operation key points to make sure the equipment running in the best condition.

After-sale service

We provide installation, debugging, maintenance, training and other services; Provide relevant technical data, equipment, software and related GMP certification materials;Set up after-sales service hotline, and arrange personnel to visit customers every year to know more customer needs,like customer operation problems in the process of production equipment.

Quality promise

Our company promises strictly operate the ISO9001 quality system certification standards and pharmaceutical equipment GMP audit requirements,promise we provide new equipment. Advanced technology,good quality.Equipment operation safe reliable, affordable, easy to maintain.

Equipment warranty period is one year,all the parts for the equipment choose well-known brand.

During the warranty when equipment have problem in quality like equipment failure and damage,the company for free maintenance or replacement.

We look forward to cooperating with partners from all over the world to build win-win cooperation relationship in long term. Welcome for your visiting.

Send to us