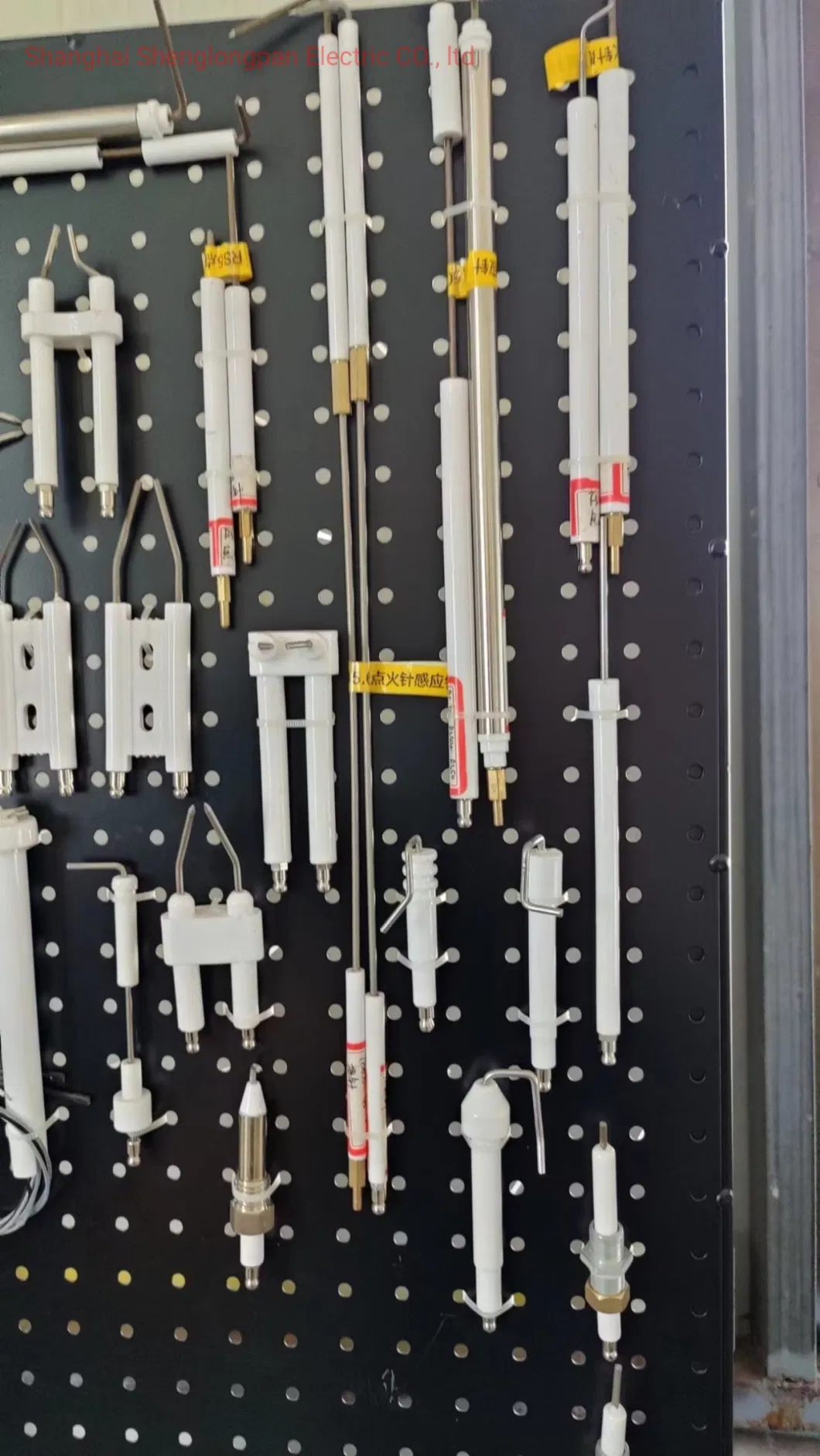

Supply Ceramic Igniter Electrode Spark Ignition Electrode for Stove /Oven Burner

Ceramic ignition needle ceramic ignition rod daily use principle Ignition mode The ignition mode of gas stove mainly inc

Basic Info.

| Model NO. | needle |

| Certificate | RoHS,SGS |

| Material | Alumina Ceramic |

| MOQ | 50PCS |

| Density | 3.6g/cm3 |

| Feature | High Temperature Resistance, Insulation |

| Samples | Available |

| Size | Customized Size |

| Alumina Content | 95% |

| Working Temperature | 1450-1600 Degree |

| Model Number | Ignition Electrodes |

| Application | Gas Ovens, BBQ, Water Heaters and Boilers |

| Transport Package | Carton Box |

| Specification | 2mm*15cm |

| Trademark | shenglongpan |

| Origin | Jiangsu |

| HS Code | 8511909000 |

| Production Capacity | 50000000/Month |

Product Description

Ceramic ignition needle ceramic ignition rod daily use principleIgnition mode The ignition mode of gas stove mainly includes electronic pulse ignition and piezoelectric ceramic ignition. Embedded stove mostly uses electronic pulse ignition mode. When it reaches a certain position, it ignites, and its ignition hit is high, generally 100%, but this way needs to change the battery.The benchtop stove mostly uses the piezoelectric ceramic ignition mode, its ignition success rate is greatly affected by the environmental humidity, the ignition needs to hold down the switch to start the fire

The ignition needle is generally not easy to break, if the ignition needle does not discharge, it may be the battery is out of power, or the pulse igniter fault, not necessarily the ignition needle problem, if the new battery or not ignition, it is recommended to find the manufacturer after sale door inspection.

The ignition methods of gas ceramic ignition needle and ignition rod are mainly divided into two kinds: piezoelectric ceramic ignition and electric pulse ignition.Modern gas cooker igniter is mostly pulse igniter, pulse igniter is a pulse high frequency oscillator composed of electronic components, it is generated by the oscillator high frequency voltage through the boost transformer to 15KV high voltage, discharge, by the discharge spark igniting gas on the gas cooker.This igniter ignites and can discharge continuously.Press the knob, pulse igniter starts ignition;Release the knob and the pulse stops the ignition.

Technical Parameters

| Table of Ceramic Materials Performance | Name | Steatite Ceramic | Cordierite Ceramic | Mullite Ceramic | 95% Alumina Ceramic | 99% Alumina Ceramic | ||

| Properties | Symbol | Units | C221 | C520 | C610 | C795 | C799 | |

| Open (apparent) porosity, maximum | ρa | Vol% | 0 | 20 | 0 | 0 | 0 | |

| Bulk density, minimum | ρa | Mg m-3 | 2.7 | 1.9 | 2.6 | 3.5 | 3.7 | |

| Flexural strength, minimum | Unglazed | ft | MPa | 140 | 30 | 120 | 280 | 300 |

| Glazed | fg | MPa | - | - | - | - | - | |

| Modulus of elasticity, minimum | E | GPa | 110 | 40 | 100 | 280 | 300 | |

| Mean coefficient of linear thermal expansion | α30-100(30 ºC to 100ºC) | 10-6 K-1 | 6 to 8 | 1.5~3.5 | 5~6 | 5~7 | 5~7 | |

| α30-300(30 ºC to 300ºC) | 10-6 K-1 | 7 to 9 | 1.5~3.5 | 5~6 | 6.5~7.5 | 6~8 | ||

| α30-600(30 ºC to 600ºC) | 10-6 K-1 | 7 to 9 | 2~4 | 5~7 | 6~8 | 7~8 | ||

| α30-1000(30 ºC to 1000ºC) | 10-6 K-1 | 8 to 10 | 2.5~5 | 5~7 | 7~9 | 7~9 | ||

| Resistance to thermal shock, minimum | △T | K | 100 | 300 | 150 | 140 | 150 | |

| Electric strength, minimum* | Ed | kV mm-1 | 20 | - | 17 | 15 | 17 | |

| Withstand voltage, minimum | U | kV | 30 | - | 25 | 18 | 20 | |

Regarding the delivery,we support each courier to send you our products.Such as, UPS, TNT, FEDEX, DHL ,SF and so on.

FAQ >>>

1

Q:Are you a factory?

A:Yes. Our factory was established in 2009.

2

Q: Will you accept customized requirement?

A: Of course, customized service is surely acceptable. Welcome to send us your drawing and more detailed specification parameters.

We can supply you the products as per your specific requirements.

3

Q:Can we order products?

A:Yes. We can design and produce according to customers'requirements. ODM/OEM orders are welcome.

4. Q:Could I get some sample?

A: Yes, its our honnr to offer sample for your reference.just let us know once you need.

5

Q: What's the delivery time for sample?

A: Generally it shall take 5~7days. For certain products, we need to prepare the materials for it. That depends.

previous:

Electrode Oven Drying for Turmeric

Dhz :next

Send to us